Ford Mustang V6 1994-2004: Why Won't My Car Start?

Does your Mustang crank continuously without starting? Perhaps the engine does not crank at all? This article will provide a basis to determine the problem area that is keeping your Mustang from starting.

This article applies to the V6 Ford Mustang (1994-2004).

Fuel, compression, and ignition are all essential elements for proper operation of an internal combustion engine. Additionally, a good power source is necessary to operate the starter motor and supply power to the powertrain control module for initial engine start-up. A problem with any one of these components can leave you and your Mustang stranded with a no-start condition. Fortunately, many problems that hinder the start-up of the engine can be quickly identified as well as replaced to get your car up and running again. This article will outline the necessary steps in determining why a 1994 to 2004 V6 Mustang will not start.

Materials Needed

- Digital multimeter

- Test light

- Battery tester

- Remote starter switch

- Screwdriver

- HEI spark tester or old spark plug

- Metric/American wrench and socket sets

- Allen (Hex key) wrench set

Step 1 – Check battery

The most common problem associated with a no-start condition is a dead battery. A battery that is low or completely dead will not have enough power for the starter to crank the engine over. Similarly, a low battery typically will not supply sufficient power to the powertrain control module that controls various engine functions, such as spark and injector pulse widths. Turning the key to the "ON" position and monitoring the voltage gauge on the dash can give you a general idea of the available battery voltage; however, checking battery voltage with a digital multimeter or battery tester will give a more accurate reading of its charge. Normal battery voltage should be approximately 12 volts or higher. If the battery voltage measures at a normal level, check all electrical connections at the battery to ensure they are clean, tight, and making good contact, as a bad ground will cause excessive voltage drop, thus reducing battery effectiveness. If battery voltage is low or dead, consider charging the battery, jump starting the car, or replacing the battery altogether.

Related Articles

- How to Replace Battery - MustangForums.com

- Why is My Battery Not Charging? - MustangForums.com

- How to Jump Start Battery - MustangForums.com

Pro Tip

While it is common for a battery to suddenly fail and need replacing, a low or dead battery may also be caused by a charging issue or an excessive parasitic draw on the battery.

If your battery is good but the engine does not crank, proceed to Step 2. If your engine cranks but does not start, proceed to Step 3.

Step 2 – Check starter

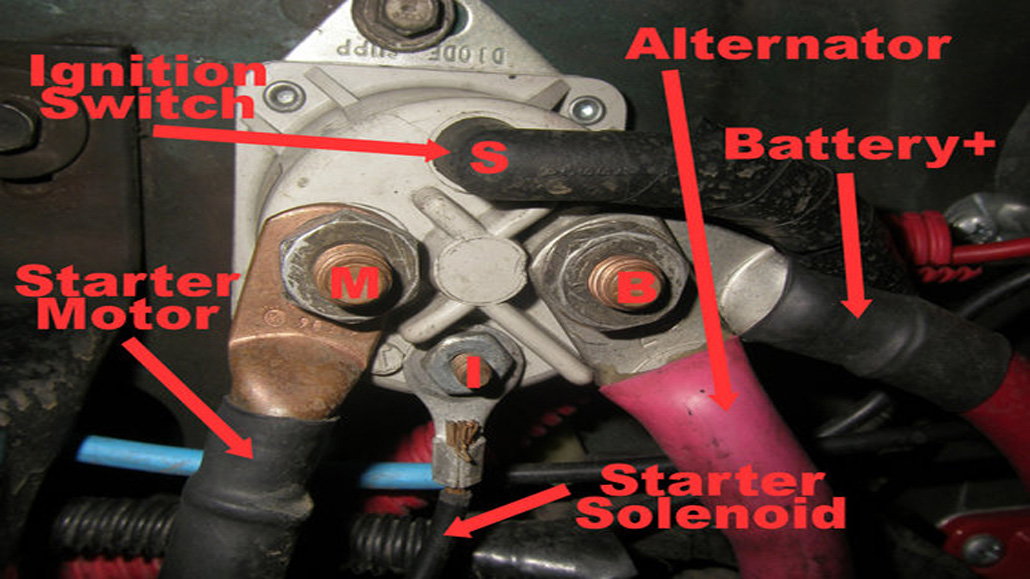

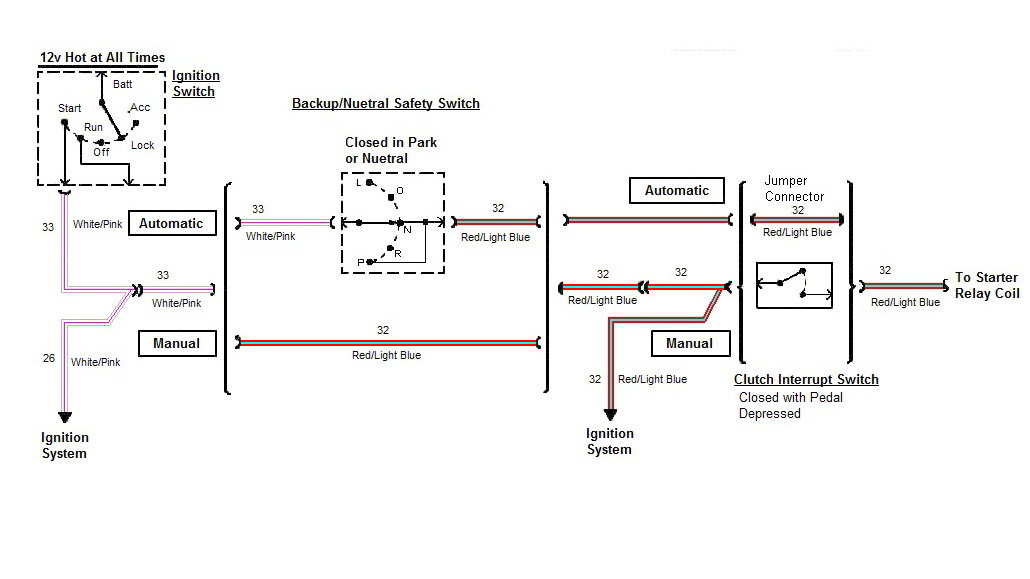

If your battery is in good condition but the car will not crank, the problem lies within the starter circuit. The starter circuit includes the ignition switch, neutral safety switch (automatic transmission), clutch safety switch (manual transmission), starter solenoid, and all associated wiring. Be sure to inspect all fuses and relays prior to diagnosing starter circuit issues.

- With the car in park or neutral, attempting to manually energize the starter solenoid will indicate if the problem is in the solenoid itself, or elsewhere in the starter circuit. Depending on the year model of your Mustang, it may have a starter relay attached to the firewall that distributes power to the starter solenoid. At either the starter relay or starter solenoid, use a remote starter switch or screwdriver to jump power from the battery to the starter. If the engine does not crank, the starter relay/solenoid is defective and should be replaced.

- If the engine does crank, the problem is most likely within the neutral safety switch or the clutch safety switch. A test light or digital multimeter can be used to check for voltage on both sides of either switch type with the transmission in park/neutral (automatic) or with the clutch depressed (manual). No voltage equals a faulty switch.

- In rare cases, the ignition switch has been known to fail. Some owners have reported the tumbler assembly breaking and causing the key to lock-up, whereas others have experienced faulty contacts in the ignition switch that inhibits starting.

Figure 2. Typical Ford starter relay.

Figure 3. Starter circuit wiring diagram.

Figure 4. Ignition switch located under steering column housing.

(Related Article: How to Replace Starter- MustangForums.com)

Pro Tip

It is worth noting that the neutral safety switch on automatic transmissions can rotate out of adjustment and not allow the car to crank when in park. If the car will start with the transmission in neutral but not in park, attempt to adjust the switch before replacing the entire unit.

If the engine cranks freely, proceed with inspecting the fuel and ignition systems.

Step 3 – Check fuel supply

If your engine cranks freely but does not start, it may have a fuel delivery problem. In most cases, a failed fuel pump or clogged fuel filter will prevent the car from starting.

- Perhaps the simplest way to check for fuel supply to the engine is at the Schrader valve on the fuel rail. If no fuel is present, there are several steps that can help determine the problem.

- The fuel pump should run for several seconds each time the key is cycled to the "ON" position. Testing the fuel pump's operation typically begins at the Inertia Fuel Shutoff Switch (IFS) located in the trunk. The IFS switch is in place to cut fuel supply in case of an accident; however, large potholes or a blown tire have been known to trigger the switch and interrupt fuel flow. With the switch button depressed, and the key in the "ON" position, check for voltage at the switch using a digital multimeter or test light. A lack of power indicates a problem upstream within the constant control relay module (CCRM), fuses, wiring, or powertrain control module. If the wiring and fuses are in good condition, test the CCRM and PCM following the procedure outlined in the factory service manual.

- If power is present at the IFS switch, the problem is most likely a bad fuel pump or clogged fuel filter, but, in rare cases, can also be a bad Fuel Pump Driver Module (99-04 models). Manually energizing the fuel pump with 12 volts can determine if the fuel pump is operational or if the FPDM is the root of the cause cause. Additionally, disconnecting the fuel filter inlet line and energizing the fuel pump by turning the key on can indicate if fuel is being pumped to the fuel filter. Upon confirming that the fuel pump is operational, the fuel filter outlet line can be disconnected and inspected for fuel. Lack of fuel at the filter outlet with the pump energized indicates a clogged fuel filter that needs replacing.

Pro Tip

Ford recommends a fuel filter maintenance interval of 30,000 miles. Replacing your fuel filter would be worthwhile if you are unsure of the last time it was serviced.

Step 4 – Check for spark

The ignition system is responsible for igniting the air-fuel mixture in the combustion chambers. If the engine cranks and has a good fuel supply, the problem is most likely an issue with the ignition system.

- The quickest as well as easiest way to test for spark is to remove one of the spark plug wires from a spark plug and connect it to an HEI spark tester or old spark plug. Have a friend crank the engine while you watch the tester or old spark plugs for arcing. This same procedure can also be used to check for spark at the coil pack.

.jpg)

- The electrical harness at the coil pack can be tested for power using a digital multimeter. Disconnect the electrical harness plug at the coil pack and probe the power pin while a friend cranks the engine. If power is present, this usually points to a faulty coil pack in need of replacement. The coil pack is a known weak point on V6 Mustang models that has a high rate of failure. Additional coil pack information can be found in the related article "Symptoms of Coil Pack Failure."

- If no spark is being produced at any of the coil towers and no power is present at the coil electrical harness, proceed with testing the crankshaft position sensor (CPS) located just above the crankshaft on the passenger side of the engine. Connect each of your digital multimeter probes to each wire at the crank position sensor plug. A small wire piercing probe may be necessary for good contact. With the multimeter set to measure AC voltage, have a friend crank the engine. The multimeter should alternate between .5 to 1 volt as the engine is cranking. A lack of voltage indicates a faulty sensor that should be replaced. The resistance of the sensor can also be tested and should measure 300 to 800 ohms.

- If a no-start condition is still present, the PCM relay in the CCRM is potentially faulty. Swapping with a known good relay can often cure the issue. If all else fails, consult the factory service manual for CCRM and PCM testing procedures.

Pro Tip

Diagnosis should always begin with ensuring all fuses, relays, wiring, and electrical plugs are in good condition. A broken wire, blown fuse, or plug that is making poor contact can cause a host of problems that can result in a no-start condition.

Related Discussions

- Diagnosing: Cranks but Won't Start - MustangForums.com

- 2000 3.8L Fuel Pump Problem - MustangForums.com

- Seems Like Car Doesn't Have Enough Juice to Turn Over - MustangForums.com