Ford Mustang V6 1994-2004: Engine Performance Diagnostic Guide

While many engine performance issues can now be identified with the use of a computer, certain gremlins can sneak under the radar and require old-fashioned diagnostic techniques. If your Mustang is not performing as it should, a quick tune-up of a few common components can have it back on track in no time.

This article applies to the V6 Ford Mustang (1994-2004).

With 1994 to 2004 V6 Mustang models coming equipped with OBD-II (On-board diagnostics), various engine parameters are continuously monitored for proper engine functionality. When a problem arises, or the computer reads something out of the ordinary, the check engine light will illuminate to notify the driver of the problem. With the use of a scan tool or code reader, trouble codes can be pulled from the computer to help quickly identify the fault and allow for a speedy repair. That being said, what happens when your engine performance starts to dwindle and drivability suffers, but the check engine light is not on and there are no diagnostic trouble codes available? This article will outline the various components that can affect engine performance and drivability on V6 Ford Mustang models.

Materials Needed

- Digital multimeter

- 3/8" drive ratchet and extensions

- Metric and American wrench and socket sets

- Screwdriver

- Floor jack and jack stands

- HEI spark tester or old spark plug

- Scan tool

- Torx driver set

- MAF cleaner

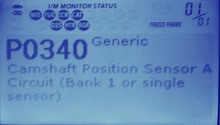

If your check engine light is on, refer to the Engine Codes Diagnostic Guide article. Reading diagnostic trouble codes can help point you in the right direction when troubleshooting an engine performance issue.

Step 1 – Check fuel filter and fuel pump

Fuel Filter

Many problems associated with poor drivability and a lack of engine performance stem from a fuel delivery problem. More often than not, fuel filter maintenance is overlooked and allows for excessive sediment to restrict fuel flow to the fuel injectors. While the engine may run fine at slow to moderate speeds, a dirty fuel filter will limit engine performance during acceleration because inadequate fuel is available to meet the demands of the requested engine load. In extreme cases, a fuel filter can become clogged to the point where the car will not start, or the engine will only run a few moments before dying. Continual driving with a restricted fuel filter can overwork the fuel pump and lead to premature pump failure.

Fuel Pump

A common problem area in many modern cars is the fuel pump. Located inside of the fuel tank, an aging fuel pump tends to become noisy with a constant whine when it is on its last leg. Rarely do fuel pumps go bad without warning, though. More often than not, owners experience drivability and performance issues where the engine lacks power, stumbles under acceleration, and bogs down with an occasional misfire. Measuring the fuel pressure at the fuel injector rail can give you an idea if the fuel pressure is within factory specifications. A lower than normal reading indicates a fuel pump or filter problem. Replacing the fuel filter is inexpensive and should be the first step in improving fuel supply, as it is the typical cause of a fueling issue. If the problem persists, focus on the fuel pump.

Pro Tip

If replacing the fuel pump, be sure to install a new fuel filter as well. A new fuel pump coupled with a dirty fuel filter can quickly cause the pump to fail. Individuals have reported new fuel pumps failing within 5,000 miles of installation because they did not replace the fuel filter.

Step 2 – Check spark plugs, coil packs and plug wires

Spark Plugs

A notorious problem area that affects engine performance on the V6 Mustang is in the ignition system. As with any spark-ignition engine, spark plugs age and their ability to properly ignite the air/fuel mixture can diminish. With use, the electrode gaps increase and dirty carbon deposits can accumulate on the ground straps, electrodes, and insulators. Inconsistent or erratic idle, poor fuel economy, and an occasional misfire are signs of aging spark plugs. With the increased voltage required to overcome excessive resistance and fire each spark plug, coil pack life can also be shortened. Spark plugs are robust and can usually keep the engine running a long time; however, a maintenance interval of 30,000 to 50,000 miles will keep it running in top shape.

(Related Article: How to Replace Spark Plugs - MustangForums.com)

Coil Pack

The coil pack on Mustang V6 models is prone to failure and can result in a variety of engine performance issues. In a nutshell, the coil pack contains an ignition coil for each cylinder and multiplies the low voltage from the battery to provide a high voltage spark at the spark plugs. This type of electronic ignition system uses various sensor inputs to provide the powertrain control module (PCM) with the necessary information to effectively control spark. While this system eliminates the need for a traditional distributor, a single failed coil will require the entire coil pack to be replaced. Fortunately, the coil pack is easily accessible and can be quickly swapped out. Testing the functionality of the coil pack is straightforward and can help you determine if that misfire or lack of engine power is due to a faulty coil pack.

(Related Article: Symptoms of Coil Pack Failure - MustangForums.com)

Spark Plug Wires

In some cases, aging or damaged spark plug wires may be the root of an engine performance issue. Spark plug wires with excessive resistance can prevent the high voltage output of the coils from reaching the spark plugs. Similarly, spark plug wires with split or cracked insulation can allow for the voltage to arc to a nearby component or even jump across to another spark plug wire and lead to misfires. A quick visual examination and resistance test using a digital multimeter can identify a plug wire that needs replacing. In some cases, a misfire or rough idle may be caused by a plug wire that is not properly seated on the spark plug or coil tower.

Pro Tip

Inspecting the spark plug wires with the engine running at night, or in a low light environment, can reveal plug wires arcing between one another.

Step 3 – Check oxygen sensor(s)

The wideband oxygen sensors are perhaps some of the most important components in any fuel injected engine. While many people associate the post-catalytic O2 sensors as being part of the emissions control system, the pre-cat, or wideband O2 sensors, monitor exhaust gases to detect if the engine is running in a rich or lean condition. This information is sent back to the PCM where fuel trim and timing adjustments are made to allow for proper combustion. A failed O2 sensor will quickly illuminate the check engine light and provide a fault code; however, O2 sensors age with use and become less effective at correctly monitoring the exhaust. Many times, the O2 sensors become slow to respond and can even measure incorrect readings, but on-board diagnostics fails to record a fault code because the sensors are still operating near the edge of their specification. Lazy throttle response and poor fuel mileage are common problems associated with aging oxygen sensors. O2 sensors can typically be tested with the engine running and measuring their voltage with a digital multimeter. Voltage should fluctuate up and down every few seconds if operating properly (between .100-1.0 volts). A fixed reading is often an indication of a bad sensor.

Pro Tip

While there is typically no maintenance interval for O2 sensors, their ability to correctly monitor exhaust gases has usually diminished by 50,000 miles. Most high performance applications recommend O2 sensor replacement every 40,000 to 60,000 miles.

Step 4 – Check air filter and mass airflow sensor

Air Filter

The air filter is a simple paper element that catches any dirt and debris before it enters the intake tract. Oddly enough, many owners often overlook this simple maintenance item as the source of their engine performance issues. A restricted air filter will choke the engine by not allowing a sufficient amount of air to be ingested into the engine for proper combustion. In fact, hundreds of cubic feet of air can flow through the engine every minute. Taking into account that the air/fuel ratio is generally around 14:1, proper air flow is a key element in the operation of any engine. The most noticeable symptom of a dirty air filter is reduced fuel mileage and general lack of performance while under load. Air filters are just about the most inexpensive item to replace on your Mustang, so replacing it every 10,000 to 12,000 miles is generally recommended.

(Related Article: How to Replace Air Filter - MustangForums.com)

Mass Airflow Sensor

The Mustang uses a mass airflow sensor (MAF) to measure the amount of air entering the engine. The heated "hot-wire" in the MAF produces a voltage signal that is affected by the air passing over and cooling the wire. This voltage measurement is forwarded to the PCM and works in conjunction with the O2 sensors to ensure proper fueling for the required engine load. Unfortunately, the MAF is prone to several problems that can cause engine bucking, poor fuel mileage, diminished acceleration, and rough idle/stalling. Most commonly, the hot-wire becomes contaminated because of a dirty air filter or blow back through the intake and prevents proper voltage signaling to the PCM. That being said, the MAF can often be removed with a Torx driver and cleaned to restore functionality. Additionally, air leaks downstream of the MAF can cause engine performance issues because the engine is ingesting additional air that is not being measured by the MAF and calculated by the PCM. The most common area for leaks is between the MAF and throttle body.

Pro Tip

Aftermarket air filters or cold air intake kits have been known to cause MAF issues. These types of air filters typically have a heavy application of air filter oil that will contaminate the MAF hot-wire. Cleaning the filter and applying a conservative amount of filter oil will reduce MAF contamination.

Related Discussions

- Engine Bogging Down - MustangForums.com

- 2001 V6 Intermittent Loss of Power - MustangForums.com

- Vibration and Loss of Power - MustangForums.com