Ford Mustang GT 1996-2004: Performance Diagnostic Guide

You cannot have a Mustang GT with performance issues. A few troubleshooting steps will help narrow down the possibilities and get it resolved.

This article applies to the Ford Mustang GT (1996-2004).

When you push the accelerator on your Mustang GT, sluggish acceleration is the last thing you would ever expect. Yet, performance issues are a possibility and it's important to determine the problem to get it fixed before it escalates any further. This requires some detective work and a lot of patience. This article will help you narrow down the possible culprits one step at a time.

Materials Needed

- Ratchet with extension

- 5/8" spark plug socket

- 10mm socket

- Flat head screwdriver

- Fuel pressure gauge

- Carburetor cleaner

Step 1 – Take a detailed test drive

Hop in the Mustang and drive it in a way that gives you as much data as possible. Try changing up your driving style to check the car's performance in a variety of conditions, such as:

- Slow and fast acceleration from a stopped position.

- Driving along at a steady speed and then punching it.

- Accelerating up a hill.

- Let off the gas and then hit it hard.

Basically, you want to put the engine through a series of stress tests to see how it performs in all kinds of conditions. All your senses should be fully engaged, taking note of the sound and feel of the engine throughout your ride. Take a friend with you to help pick up something you might have missed or vice versa.

Step 2 – Transmission or engine issue?

This is a tough one to gauge because the symptoms can be similar. A simple test you can do for an automatic transmission is to shift the gears manually. Start by putting the car in manual first gear. If the same problem still occurs in manual first gear, then you can reasonably rule out a transmission issue. This is by no means a sure fire test, but it helps in the troubleshooting process. A trip to your local transmission specialist might be worthwhile, as many will perform a free transmission analysis for you.

Step 3 – Check the basics

Always start with the basic performance issues before digging any deeper. Here are some of the more common causes of performance issues:

- Clogged air filter

- Clogged fuel filter

- Spark plugs and wiring

- Distributor cap

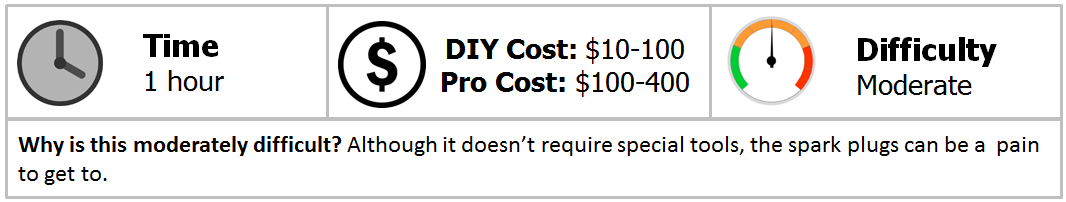

The spark plug should be the first stop on any performance evaluation. Pull out the closest spark plug and take a look. First, it is highly recommended to use the manufacturer's recommended plugs. They are engineered to a certain spec that a cheap replacement cannot emulate. Also, look for general signs of wear to indicate if it's time for some new plugs. Ignition systems are so tightly designed these days that the slightest inefficiency in plug performance can be magnified on the road. Use good plugs to get the best performance.

Step 4 – Check the fuel pressure

With the spark plugs firing correctly, it's time to look at the fuel delivery to the engine. Obviously, if you're able to drive down the road, you know the fuel pump is functioning. A clogged fuel filter, however, can reduce the fuel pressure and volume, causing performance issues. A fuel pressure gauge is the best tool for this job because it allows you to check the fuel pressure going into the filter and coming out of it. Check against the manufacturer specs to see if the pressure is correct. See Figure 4 for some sample readings.

If you see a drop off in pressure coming out of the filter, then you likely have a clogged filter. If you don't have a fuel pressure gauge, then installing a new filter is still worth the investment, especially if it's been a while since the last filter change. A new filter can't hurt.

Step 5 – Airflow and other possible issues

We've already mentioned the air filter being clogged, but there are other less obvious air flow problems that could be happening. At the heart of this air system is the mass airflow sensor. It detects incoming air flow and sends it to the engine computer for use in calculating the proper fuel mixture ratios. If there are leaks in the airflow system beyond the mass airflow sensor, the computer won't know about them and will throw off the calculations, which can affect the engine performance.

Start by checking all of the air pathways from the air filter through to the throttle body. Check for holes, cracks or loose connections that may cause an air leak. You can spray carburetor cleaner around any areas you might suspect are leaking, while the engine is running and listening for any changes in the engine idle. That would indicate a leaky area that you can fix.

If no air leaks are obvious, then it's time to clean your mass airflow sensor. They do sell mass airflow cleaning spray that you simply spray onto the sensor itself as shown in Figure 5. Just spray it on and let it sit for a few minutes, and then reinstall the sensor.

If all of these steps have been taken but there still seem to be issues, here are a few other possibilities:

- Bad fuel injector(s)

- ECU problems

- Voltage leaks

- Bad compression

- Exhaust leaks and catalytic converter problems

- Clogged fuel vents

Featured Videos: Solving Engine Performance Issues

-

Part One

-

Part Two

Related Discussions

- Hesitation Problems Solved - MustangForums.com

- Performance Issues - MustangForums.com

- Common Problems - MustangForums.com